It’s here! The Mother of All Piers. The MOAP.

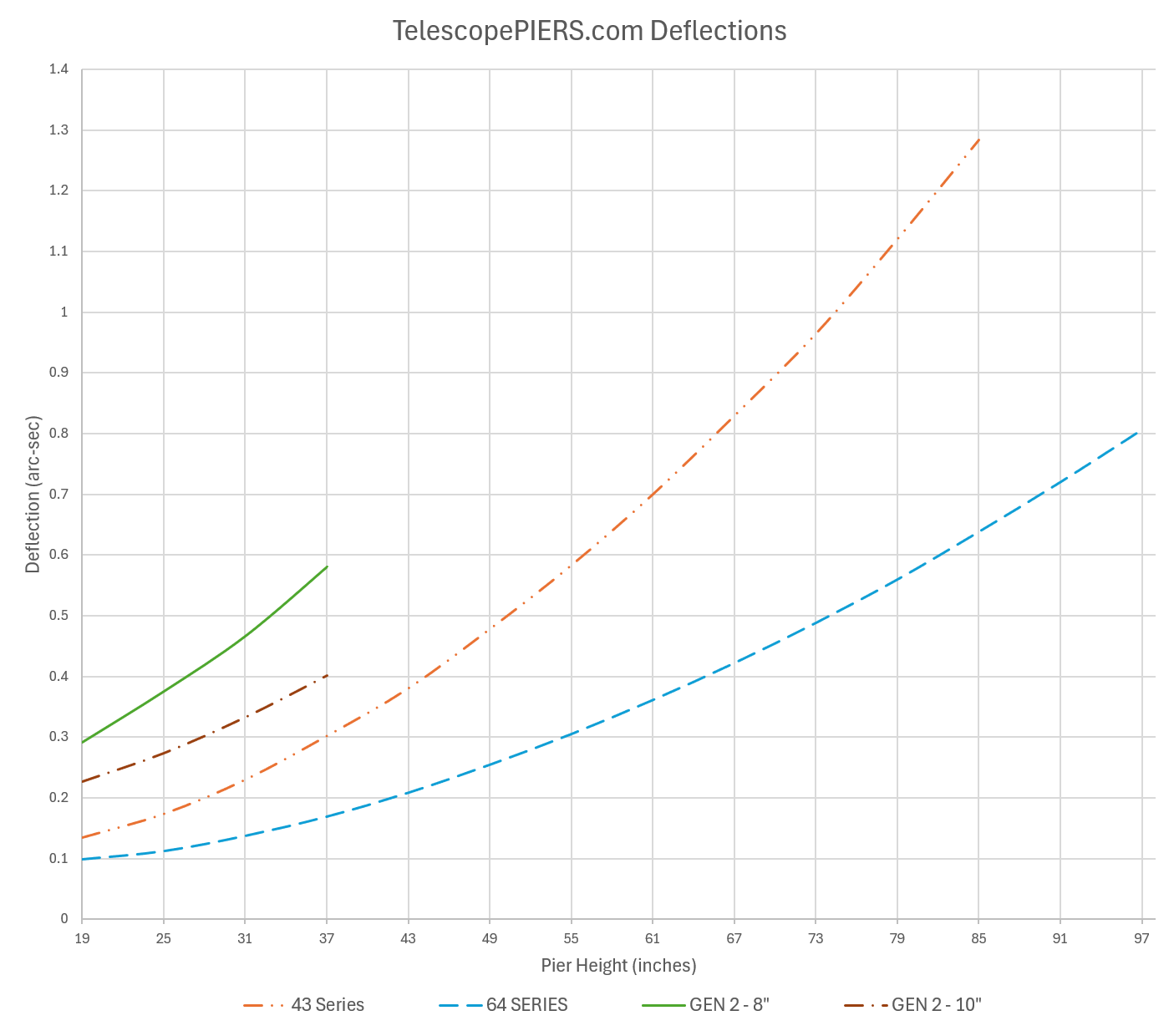

Next level engineering brings you the stiffest, most stable permanent observatory custom telescope piers available. It’s all about deflection and MOAPs have 3x to 20x less deflection than other telescope piers on the market. Much more rigidity and greatly reduced movement mean superior performance, higher capacity, and dependable handling of critical tasks while still competitively priced.

Completely customized to your specific mounts and desired pier height. MOAPs can be prepped for existing anchor bolts if you already have a foundation. Alternate configurations, such as equatorial piers, are also available.

Directly attach your telescope mount or adapter to the Mount Plate pre-drilled and tapped for your equipment.

Future proof telescope pier for heavier payloads and smaller pixel scales. Easily move the MOAP telescope pier when you move. Using multiple mounts on a single MOAP is a simple, quick change out and a single Mount Plate can be prepped for multiple mounts.

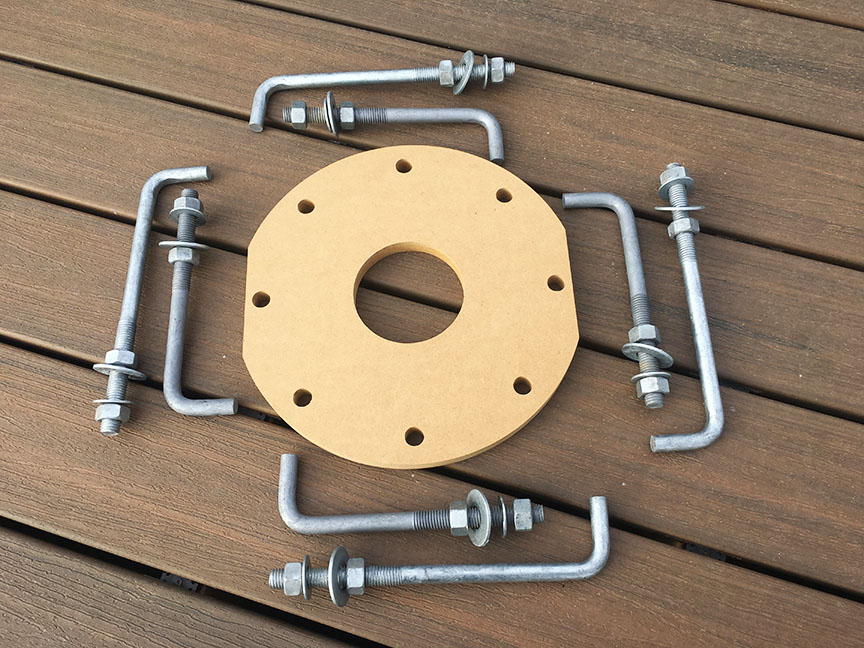

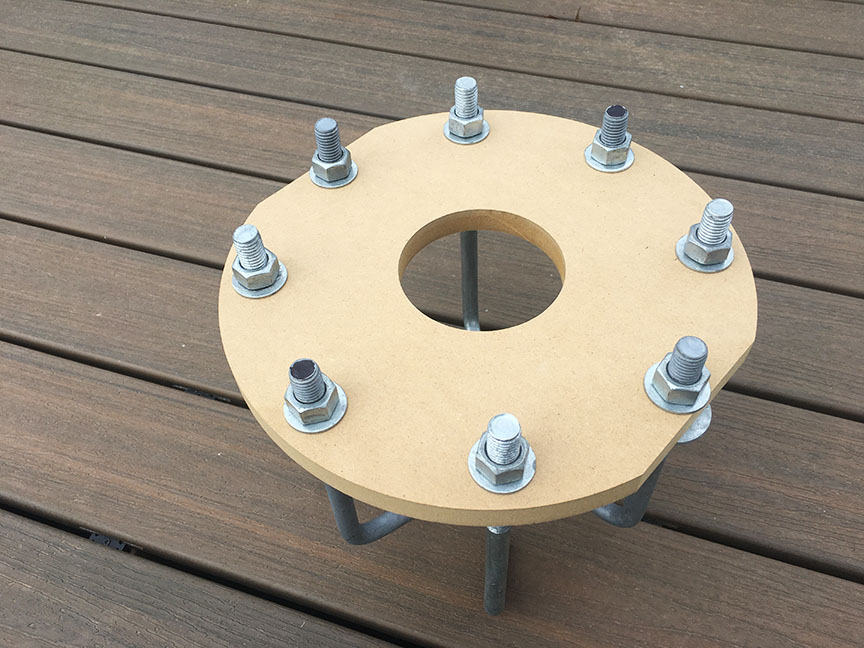

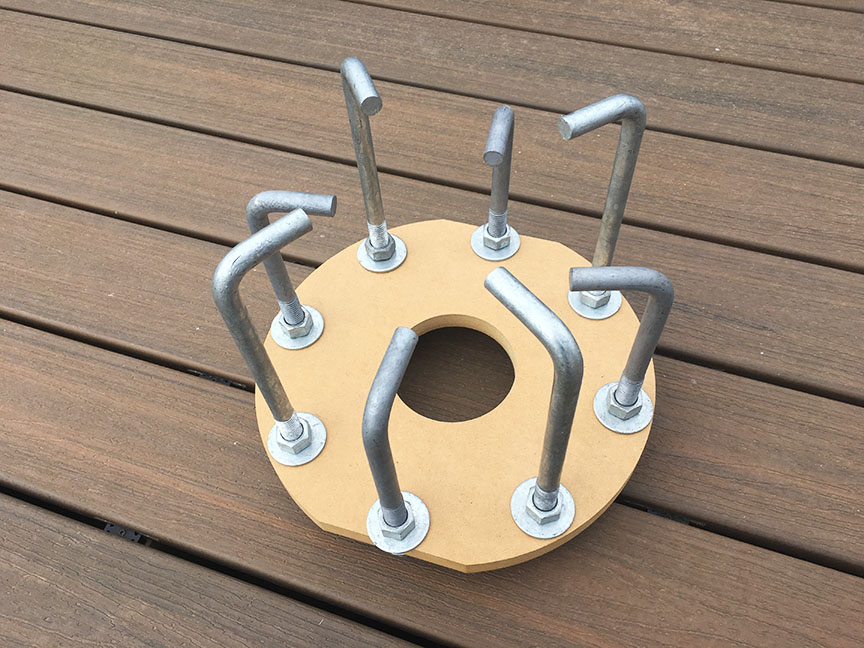

Take the guesswork out of pier installation with CNC anchor bolt templates and Base Plate slots with 10 degrees of adjustment for precision PA. Fast, easy pier leveling at the base while keeping the pier off the concrete eliminates the need for undesirable flexing top plate leveling. ($4m wind turbines do it the same way.)

Superior cable management inside the MOAP telescope pier provides room for two 1-1/2″ plus two 3/4″ conduits.

MOAPs have 3 design varieties:

-

43 SERIES telescope piers are designed around 8″ pipe with deflections of less than 0.40 arcsec for heights up to 43″.

-

64 SERIES telescope piers are designed around 10″ pipe with deflections of less than 0.40 arcsec for heights up to 64″.

-

GEN2 telescope piers are designed for smaller foundations or shorter heights with the unique feature of having anchor bolts inside the pipe. Deflection is less than 0.40 arcsec for heights up to 34″.

Click here to check out the GEN2 solutions!

All MOAP telescope piers feature:

- Powder coated steel pier body and Mount Plate. Pre-drilled and tapped for your specific mount or adapter. Pipe: ASTM A500 Grade B, 46,000 psi yield, 58,000 psi tensile. Plate: ASTM A36, 36,000 psi yield, 58,000 psi tensile.

- Stainless steel Mount Plate fasteners: ASTM F879 alloy group 1, condition CW, 65,000 psi yield, 125,000 psi tensile. ASTM A380/A380M finish. 4,940# clamp load.

- Anchor Bolt Kits take the problems out of installation. CNC template and 5/8″ hot-dipped galvanized anchor bolts: ASTM A36/A36M & ASTM F1554 Grade 36, A563 grade A, ASTM A153. 36,000 psi yield, 58,000 psi tensile. 14,400# clamp load.

- Step-by-step installation guide (how to easily nail pier alignment, cast the anchor bolts, level the pier, properly torque bolts, etc.)

- Concrete Foundation Design and Installation Guide: How to get the most of what you put in the ground.

- Customer support on your schedule. We are here to make sure everything goes smoothly.

- Lifetime structural warranty.

Click here to enlarge the graph

Click here to enlarge the graph

Telescope pier components are cut by a 5-axis CNC water jet providing quality 5 (best) edges. Pipe sections are put in a lathe and the cut ends are faced and beveled in preparation for welding. Fabricated piers go back in a lathe and the top plate is faced to remove any thermal deformation from welding processes. Surface contaminants are removed and the assembly is abrasive blast cleaned to grade SSPC-SP6 prior to powder coating with a proprietary hybrid urethane/polyester resin. Materials are critical to achieving low deflection. We use new domestic steel and fasteners meeting the following specifications:

- Pipe: ASTM A500 Grade B, 46,000 psi yield, 58,000 psi tensile

- Plate: ASTM A36, 36,000 psi yield, 58,000 psi tensile

- Stainless steel fasteners: ASTM F879 alloy group 1, condition CW, 65,000 psi yield, 125,000 psi tensile. ASTM A380/A380M finish. 4,940# clamp load.

- Hot dipped anchor bolts: ASTM A36/A36M & ASTM F1554 Grade 36, A563 grade A, ASTM A153. 36,000 psi yield, 58,000 psi tensile. 14,400# clamp load.

Everything vibrates. Even the back of your eye has a resonant frequency. A telescope pier has not one but several modal frequencies. Fundamental frequency corresponding to first modal shape is called the natural frequency of the system. Increasing stiffness increases the natural frequency. Increasing the mass decreases the natural frequency. An increase in the damping diminishes the peak response but broadens the response range. What does this mean to our properly designed telescope piers? Absolutely Nothing! Since the magnitude of the vibration is less than our piers' deflections, less than the camera can detect, it doesn’t matter if it’s vibrating at 40 Hz, 400 Hz, or 4,000 Hz.

A steel pier's high pitch is a good thing. The higher, the better.

Please contact us to answer questions and define the specifics of your pier. Call or text Jim at 325-669-2584 or email us at

Information we need:

- Your contact information.

- Your mount model(s).

- Your desired pier height from top of concrete to bottom of mount.

- If you need an anchor bolt kit shipped early or with your pier.

- Include a Benton Tab or Thompson tab accessory?

- Any other features your pier needs.

- Your shipping address for freight quotes.

We send you detailed drawings of your pier for your review and approval, followed by a link to your payment portal.

You will soon be in the MOAP family of astronomers!

43 SERIES, <0.4 arcsec deflection up to 43″ high:

$1,448.00

64 SERIES, <0.4 arcsec deflection up to 64″ high:

$1,648.00

GEN2, <0.4 arcsec deflection up to 34″ high:

$1,298.00

Anchor kit:

$80.00

(CNC template, 5/8″ ASTM A36 G90 galvanized anchor bolts with nuts and SAE and USS washers, 4″ thread length. Can be shipped in advance of pier)

Benton Tab accessory:

$290.00

Thompson Tab accessory:

$150.00

Installation and Foundation Guides:

included

Customer Support on your schedule:

Included

We want to hear from you!